The etymological meaning of the word "metrology" comes from the ancient Greek "metre" and "treaty". By extension, this corresponds to the science of measurement.

The question asked here is therefore "what is measurement?".

To measure is to compare

Let's first think about how to make a measurement.

The measurement is present in everyday life: in a kitchen to weigh ingredients, in a medical analysis laboratory to diagnose diabetes, in institutions to qualify the level of urban pollution, in research laboratories working on particle detection, in industry for control and manufacturing. Each time, the process is the same: two things are compared.

For this, two prerequisites are necessary. The elements must be comparable (the method used must allow a reliable comparison) and the instrument used must be reliable and qualified.

This principle is fully illustrated with a Roberval scale, an instrument that can measure masses (fig. 1).

In fact, it compares the value of the mass of an object ("objet à mesurer"), unknown, to that of a known reference. In metrology, the term "mass comparator" is used. Once the comparison is established, a numerical value of the mass sought is accessed via the instrument which allows quantification with the appropriate unit.

All measures are based on this principle:

- For a dimensional measurement, the ruler or tape measure is both the reference and the measuring instrument;

- For a mass measurement, a set of "weights" is the reference, the instrument is a scale.

- For an electrical current measurement, a multimeter is both the reference and the measuring instrument.

The international system of units, the SI, in force since 1960, allows all physical or chemical phenomena to be described on the basis of its constituent units and quantities.

Key points

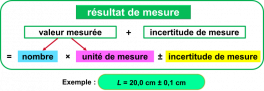

- The measurement of a quantity Q is :

- A numerical value {Q}

- A unit [Q]

- A measurement uncertainty

- It's expressed as the product of a numerical value and a unit : $Q=\left\{Q\right\}\times\left[Q\right]$

Interest of metrology

Accessing knowledge often involves a number and the measurement which produces this number is not possible without units, standards and measurement instruments. This is the role of metrology, which is not only an individual discipline of the physical sciences but the base of our daily activities. Like Molière's Monsieur Jourdain who spoke prose without knowing it, we all use metrology without realising. Mr. Christian Pierret presented metrology and its various applications during a communication in a Cabinet meeting on 2 December 1998, entitled "new ambitions for metrology at the service of competitiveness ". The above extract reminds us that measurement is a scientific, economic and social necessity :

Measurement increases knowledge

In fundamental research, metrology is present at every step. It is used to design the conditions for observation of a phenomenon, to build and qualify the instruments required for its observation and to determine whether the results obtained are significant. Rock dating, characterisation of gravitational fields, determination of certain chemical or physical constants all involve measurement activities.

Measurement protects people

- Dosing of drugs or measurement of radiation in radiotherapy, food safety and many others require measuring operations that are vitally important activities for public health. The reliability of measurement instruments in operating theatres or intensive care units is critical.

- The application of labour law involves a system to monitor the hours worked, the noise and lighting levels in the workplace, measurements of ambient atmospheres (mercury vapours, fibres and particles), etc.

- Road safety implies restrictions on speed, alcohol and vehicle braking efficiency as well as measurements to ensure that they are respected.

- Protection of the environment implies statutory requirements on nuisances and the quality of air and water, and involves measurements.

Measurement governs transactions

- All transactions made by individuals and companies involve measurements: dosing of foodstuffs, metering subscriber gas consumption or cross-border counting, petrol at the pump or on the pipeline, retail or bulk weighing, etc.

- Measurement is an essential factor in the relations between customers and subcontractors. In the absence of reliable measurements, it is impossible to guarantee that the subcontracted parts will match the customer's requirements.

Measurement enables our industries to be innovating and competitive

- Competitiveness involves quality, which is the ability of a product to meet consumer and user requirements, and which involves all types of measurement in order to study and satisfy customer expectations (organoleptic measurement in agribusiness, performance measurements for industrial products, etc.). Quality can be demonstrated to customers through certification, itself based on measurements.

- Competitiveness assumes that industry measures and precisely controls the production volumes and the performance of the production tool, and that it minimises the costs of rejects and rework operations.

The description of these different applications leads us to make a distinction between fundamental and legal metrology. On the one hand, fundamental metrology is concerned with the creation, maintenance, improvement and transfer of metrological references. This activity is carried out by the national metrology laboratories, prior to any technological application. It is therefore important to remain attentive to the ongoing changes in the fields of industrial processes and applications, especially health and environment related applications. On the other hand, legal metrology represents one of the State's civic missions which consists of guaranteeing the reliability and stability of measurements for commercial or statutory use and preventing fraud. Metrology then becomes a means of economic regulation.

Defining references

The notion of reference is essential. Since these references are used for ongoing comparisons with other objects, they must offer guarantees on the following points:

- Durability: their stability over time must be sufficient and adapted to the need for measurement;

- Uniformity: sampling should not alter its accuracy;

- Accessibility: the comparison must be easy to make, by everyone, and at the moment when the need is expressed.

All these elements must be delivered with the best possible accuracy.

The mission of the national laboratories is to deliver the first reference level, with the best uncertainty at national level, for the 7 basic quantities, called "national references".

The SI makes it possible to ensure the unification of measurements on a worldwide scale. The national references are the practical implementation of the definitions of each base unit and the high level references for derived units. The references can be of 3 different types:

- A practical application of the definition of the unit;

- A reference material;

- A reference procedure or instrumentation.

In practice, each laboratory of the French national metrology network is the depositary of the national references in its field: it is the master of the development of these references (within the limits of the finances granted to it) and the guardian of its maintenance over the long term.

In some cases, depending on public utility or political orientations, specific references, in addition to those corresponding to the seven basic quantities, are developed and maintained as necessary.

This is the case for certain derived units, such as hygrometry or flowmetry, required by air conditioning or refrigeration equipment manufacturers. It is also the case for the nuclear industry and radiotherapy, which require a multitude of references in terms of radioactivity measurement and dosimetry.

Key points

- Having references is essential to ensure the results provided by instrumentation

- The references with the best uncertainties on the French scale are those issued by the French National Metrology Network

Evaluating uncertainties

The comparison being established with an available reference, one reaches the numerical value sought of the considered quantity, via the instrument which allows quantification. However, uncertainty remains.

The latter actually quantifies the doubt we have on the value of the measured quantity. In particular, it allows two results to be compared.

Without uncertainty, we understand that any comparison of two results makes no sense.

This uncertainty is related to the measurement operations and takes into account all the parameters that can induce an error on the final value: from the choice of the reference to the measurement range, via the experimental conditions. A whole series of parameters must be precisely analysed before establishing what is called an "uncertainty budget" which makes it possible to calculate the overall measurement uncertainty.

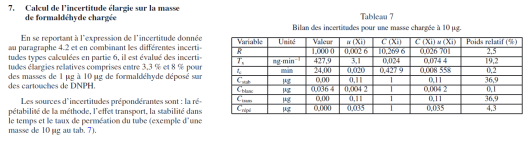

Here is an example of an uncertainty budget on the measurement of the mass of formaldehyde deposited on DNPH cartridges (extract from an article published in the Revue Française de Métrologie : n° 41, Vol. 2016-1, 29-39) :

Each calculation of uncertainty is specific to the measurement principle under consideration, and the method of establishing such a balance is described in the guide prepared by a joint International Committee of Guides in Metrology under the auspices of the BIPM: "EVALUATION OF MEASUREMENT DATA - GUIDE TO THE EXPRESSION OF MEASUREMENT UNCERTAINTY". It is available in its electronic version on the BIPM website.

In general, the uncertainty of the measurement result is expressed as a standard deviation, which takes into account all sources of measurement uncertainty. There are two types of uncertainties:

- Type A evaluations of measurement uncertainty, which result from an evaluation by statistical analysis of series of observations;

- Type B evaluations of measurement uncertainty, which result from the phenomena and physical properties involved, calibration certificate values or other specifications

The LNE makes software available free of charge for the evaluation of measurement uncertainties: https://www.lne.fr/fr/logiciels-bases-de-donnees.

Key points

Ensuring traceability

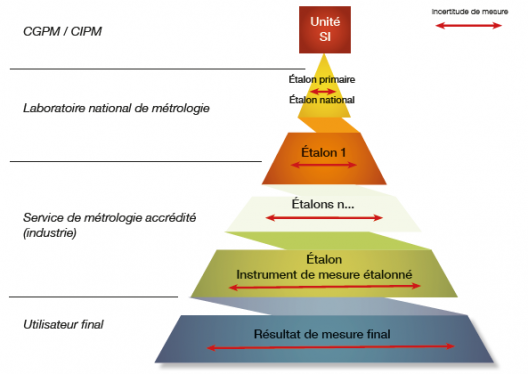

In order to allow reliable measurement in all locations, this must result from a connection to a metrological reference. Thus, a succession of comparisons to references (calibrations) is carried out, with increasingly lower uncertainties, up to the national reference, to ensure the traceability of this measurement to the SI. This defines an uninterrupted calibration chain. This metrological traceability plays an essential role for the quality of the measurement and is essential for the monitoring and assessment of the quality of a product, and ultimately for the safety and protection of consumers.

The traceability chain schematizes the dissemination of measurement standards: it is an uninterrupted chain of references and instrumentation that guarantees the connection to the unit with a given uncertainty. It is usually represented in the form of a pyramid.

At the top of the pyramid is the ultimate reference of the unit: its definition.

Next, the national metrology institute, which ensures that this definition is carried out and put into practice at national level, with the best possible level of uncertainty. This is true for base units but also for derived units.

Then follows in the chain accredited laboratories that set up instruments that guarantee uninterrupted connection with the national laboratory reference.

From top to bottom of the pyramid, there is therefore an increasing number of connections (width of the pyramid), which reflect the quantity of available reference standards, associated with increasingly large uncertainties.

This traceability chain can be applied to each SI unit.

However, although high technology has invaded everyone's daily lives, it is not always useful to use sophisticated equipment to perform a measurement. To measure time more precisely than 10-8 s or to measure the length of a frame to the nanometre may be useless.

The uncertainty required for a given measurement is first that which meets the need.

It is therefore not necessary to carry out measurements that can be directly connected to the NMIs (a request that the NMIs would not be able to access given their resources), hence the need for a set of accredited laboratories to carry out these measurements in more restricted fields of application. In order to guarantee the measurements thus made, the notion of traceability is essential.

Key points

- To have the guarantee to carry out a good measurement, it is necessary to follow its instrumentation and its drifts by regular calibrations. This ensures the traceability of measurements made with the highest level standards (national, international).

- The references with the best uncertainties on the French scale are those delivered by the French metrology network.

Universality of measurements and applications

Each nation has its own chain of traceability, usually on an independent basis. In France, the first links in this chain are provided by LNE and the other member laboratories of the national metrology network. LNE, as pilot, represents France on an international scale. To ensure the validity of measurements, all national laboratories conduct reference comparisons with their foreign counterparts to guarantee consistency and universality of measurements worldwide.

Any measurement requires multiple comparisons to ensure validity. In all fields of daily life, we therefore find the notion of metrology and connections in order to :

- Guarantee the chemical composition of products, and therefore their toxicity level before they are placed on the market

- Ensure electrical production in accordance with the installations

- Benefit from adequate care for pathologies and without risk for healthy organs

- Guarantee manufacturing according to the required specifications

- Ensuring safe transport via accurate telecommunications

- Paying the right price for a product

- Monitor the environment and take appropriate measures to maintain its quality