When this European project was launched, there was no coverage for metrological force measurement needs above 15 MN in Europe. This corresponds to industrial applications in many fields (mechanical engineering, construction, energy, etc.). To cover most of the requirements, it was estimated that it would be necessary to be able to measure up to 50 MN. This project focused on the study of “build-up systems” which are the combination of several force sensors in parallel in order to measure forces higher than those that each sensor can measure individually.

OBJECTIVES

Extending the range of force measurements above 15 meganewton

Consolidate force measurement uncertainties with force pyramid benches

Improve the calibration control of multi-component sensors

SUMMARY AND RESULTS

The LNE has long developed systems combining parallel force sensors called “Build-Up Systems” (BUS) used to calibrate force sensors between 500 kN and 9 MN. The work of this JRP focused on studying these systems and qualifying new force transfer standards. The reference pyramids, solutions implemented in the laboratory, were studied in particular in this project.

At the LNE, the BUS was only applied under increasing loads, meaning that it was not possible to determine the hysteresis of the sensors to be calibrated. For the LNE, this project was an opportunity to model the phenomena of hysteresis, creep, and relaxation in order to quantify the uncertainties of its BUS when used under decreasing loads.

Study of the behavior of Build-Up Systems

Various types of BUS in the meganewton range were studied, notably by cross-referencing measurements taken using different measurement benches implemented by the laboratories participating in the project. For the LNE-LCM, the good consistency between the individual calibration of the sensors in its BUS and their calibration in assembled position was confirmed up to 9 MN, demonstrating the absence of effects related to the introduction of forces and confirming the uncertainties announced by the laboratory.

Study of the effects of parasitic forces

Lateral forces

A 5 MN BUS capable of measuring lateral forces and moments superimposed on the main axial force was developed by INRiM based on the hexapod principle. At the same time, the calibration procedures for multi-component sensors were identified and an inter-laboratory comparison was carried out between PTB, LNE, and INRiM. The differences obtained show that the LNE-LCM test bench performs well, with low parasitic forces and consistent measurements for both vertical forces and superimposed parasitic forces.

Effect of eccentricity

On the other hand, the effect of an eccentricity between the force and the axis of the BUS. A series of measurements were taken by aligning and offsetting a sensor by 3 mm with a BUS. These showed that there is no significant effect on the LNE BUS. This confirms the uncertainties of the laboratory, which uses a device that ensures centering of around 0.1 mm for routine calibrations.

Effect of durations and loading mode

The initial aim of the work was to acquire data in order to better understand the behavior of force sensors in relation to preloads, creep, relaxation, and hysteresis.

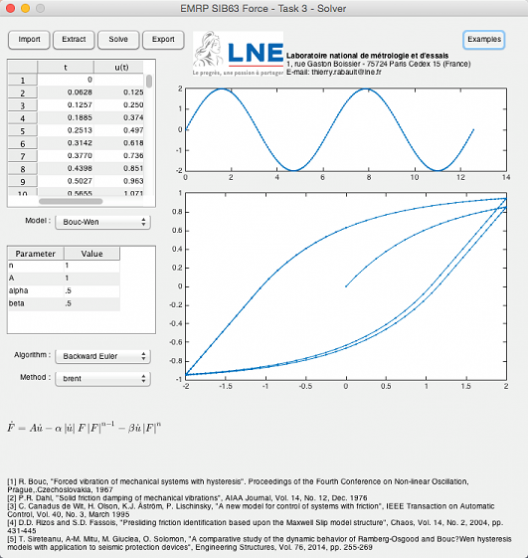

As part of this European project, a total of 229 tests were carried out using 44 different sensors covering ranges from 50 N to 5 MN. These tests focused on creep, zero return, and reversibility. Armed with this data, the objective was to develop numerical models to correct the effects associated with force sensor loading procedures. These effects include creep, zero drift (relaxation), and reversibility (or hysteresis). Hysteresis modeling software was developed. Modeling was defined for creep and relaxation.

Project outlook...

For the laboratory, the claimed uncertainties of the reference pyramids up to 9 MN have been confirmed as entirely justified, both in terms of internal stress transmission phenomena and sensitivity to parasitic forces. In addition, modeling of creep, relaxation, and hysteresis phenomena makes it possible to consider systematic corrections to the reference pyramids for measurements under decreasing loads. This will enable LNE-LCM, for forces above 500 kN and up to 9 MN, to determine the hysteresis of the sensors used by the laboratories and manufacturers it connects, and thus to better meet their needs.

PUBLICATIONS AND COMMUNICATIONS

RABAULT T., AVERLANT P. and BOINEAU F., “Numerical modeling of hysteresis applied on force transducer”, XXI IMEKO World Congress “Measurement in Research and Industry”, Prague, Czech Republic, 30 August - 4 September 2015.

KUMME R., TEGTMEIER F., RÖSKE D., BARTHEL A., GERMAK A. and AVERLANT P., “Force traceability within the meganewton range”, IMEKO 22nd TC3, 15th TC5 and 3rd TC 22 International Conferences, Cape Town, South Africa, 3-5 February 2014.

PARTNERS

- PTB (DE),

- BAM (DE),

- CEM (ES),

- CMI (CZ),

- INRIM (IT),

- METAS (CZ),

- MG (PL),

- MIKES (FI),

- NPL (GB),

- TUBITAK (TK)