The noise produced by machinery or equipment is a technical characteristic generally expressed in terms of acoustic power (power level in dB relative to a reference acoustic power of 10-12 watts). When this project was started, the experimental determination of power was based on acoustic pressure measurements taken using microphones. The acoustic power was then evaluated by calculation, under various assumptions and conditions that were not perfectly met. As a result, the connection to the international system of units was achieved by linking pressure levels through microphone sensitivity measurements. This resulted in a ‘true’ assessment of acoustic power being marred by all kinds of biases, uncorrected influencing factors and methodological errors. The situation was made even more complex by the fact that some of the acoustic power measurements used a method of comparison with reference sound sources, which were themselves calibrated using the pressure method and were quite sensitive to environmental conditions.

The aim of this project was therefore to develop and characterise a primary standard sound source and then disseminate it via transfer standards (which are the sound sources that were previously used as references). The application to machine noise was then to be carried out by developing new procedures for measuring sound power in different environments and evaluating the associated measurement uncertainties.

OBJECTIVES

Develop a reference sound source whose acoustic power can be calculated from measurements of vibration velocity, dimensions, and environmental air properties, with an uncertainty of 0.5 dB.

Measure the acoustic power of this reference sound source using sound intensity instruments calibrated in accordance with IEC 61043 and explain any deviation from the expected behaviour. This is necessary to distinguish the phase shift between the speed of sound and the acoustic pressure on the surrounding surface.

Develop methods for calibrating non-calculable sound sources by comparison with the reference sound source. The focus will be primarily on broadband sources, which generate sounds aerodynamically. Another aspect addressed is the development of a new concept for tonal sound sources.

Develop qualification procedures for measuring devices, analyse uncertainties associated with determining sound power in practice, and develop a substitute method using sound intensity for machine noise.

SUMMARY AND RESULTS

Primary standard sound source

The objective of this part was to produce a primary standard for the acoustic watt in air. This is based on a baffled vibrating solid body (piston). The sound power of this device can be determined from the vibration speed of the body's surface, measured by laser interferometry, and several other variables such as static pressure and temperature. The various candidates for primary sources are based on two techniques: an electrodynamic pot or a loudspeaker ‘motor’. The electrodynamic pot is a vibration source commonly used in laboratories. It drives the movement of a metal piston. The latter must have as much overall movement as possible and as little parasitic movement as possible, due to its lack of rigidity and its natural modes/frequencies at high frequencies. The other method involves using a loudspeaker ‘motor’ that drives a lighter piston. Guiding the piston in a unidirectional and free movement is difficult to achieve. In this project, primary sources were developed by PTB, SP, INRiM and TUBITAK UME.

Diffusion of the ‘acoustic watt’ unit

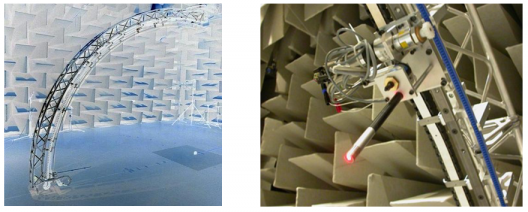

The objective of this part was to develop a system for disseminating the acoustic watt unit using appropriate transfer standards. This made it possible to examine whether existing aerodynamic reference sound sources could be used as transfer standards. The answer was positive, provided that their sensitivity to atmospheric conditions was known. The uncertainty of the sound power emitted by the transfer standards was determined. The objective was for this uncertainty to be only slightly greater than the uncertainty of the primary standard. The LNE developed a scanning apparatus for automated measurement of acoustic power by measuring the acoustic pressure on a 2 m radius hemisphere centred on a reference source flush with the ground.

At LNE, unlike other partners, a single microphone is used, moved to each position by an automatic device and controlled by software that manages both the scanning device and the acoustic signal analyser acquisition. The first movement is made along a rail describing a 90° vertical arc. The second movement consists of moving this arc around a vertical axis to cover the entire hemispherical surface. A third movement moves the microphone along a 1 cm radius to evaluate the intensity in two stages.

Project website:

PUBLICATIONS AND COMMUNICATIONS

BREZAS S., CELLARD P., ANDERSSON H., GUGLIELMONE C. and KIRBAS C., “Dissemination of the unit Watt in airborne sound: aerodynamic reference sound sources as transfer standards”, INTER-NOISE 2016, Hamburg, Germany, 21-24 August 2016.

CELLARD P., ANDERSSON H., BREZAS S. and WITTSTOCK S., “Automatic sound field sampling mechanisms to disseminate the unit watt in airborne sound”, INTER-NOISE 2016, Hamburg, Germany, 21-24 August 2016.

Partners

The work was carried out as part of the European project JRP SIB56, which included the following national metrology laboratories:

- PTB (DE),

- INRIM (IT),

- LNE (FR),

- SP (SE),

- TUBITAK (TK).